Temperature control and stability is a key indicator of Heat Transfer Roll Health. In today’s world of performance materials and adherence to international standards, uniform temperature control is essential, directly impacting line speed as well as product quality and consistency. If you’ve identified an issue with your heat transfer rolls, the decision to refurbish or replace is best made by first determining the cause of performance decline.

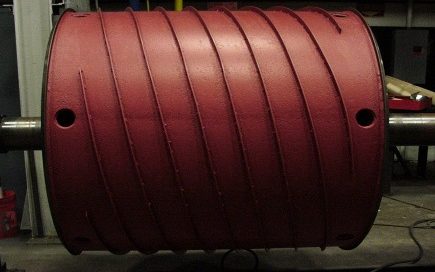

Basic maintenance of your heat transfer roll, such as running treated water through your roll or acid flushing on a regular basis, will help to maintain clean internal flow passages. When scale build-up, excessive corrosion, and blockages inside the roll are significant, roll refurbish may be a more economical option than de-commissioning or discarding the roll. At Mirror Polishing & Plating, our goal is to provide you a means to salvage usable components when possible. Removing the outer shell and reconditioning the internal components can be solutions.

At MP&P we offer an established inspection process for all incoming rolls.

Refurbishing your heat transfer roll can return production efficiency and product quality with a faster ROI than any other roll refurbish service. If the internal structure is intact and in good operating condition, the cost to reshell or refurbish an existing roll will be less than investing in a new heat transfer roll.

Frequently Asked Questions

How long does the refurbish process take?

Refurbishing a roll typically provides a 30% time savings versus a brand new roll.

What is the process?

- Remove the old outer shell

- Evaluate internal assembly to determine if the roll can be repaired

- Clean internal assembly and remove old spirals – replace with new spirals

- Apply corrosion resistant coating over entire internal assembly flow passages (optional)

- Turn and bore new outer shell for proper fit with reconditioned inner assembly

- Restore and recondition shaft (if required)

- Apply chrome plating or another coating system to complete refurbished heat transfer roll

How can I follow the status of my roll refurbish?

A work order is assigned to your project, updates will be provided.

Get Started

Engineers at MPP are available to talk through your temperature control challenges and help you evaluate whether repair or refurbish could save you time and money.