What is Acid Flushing?

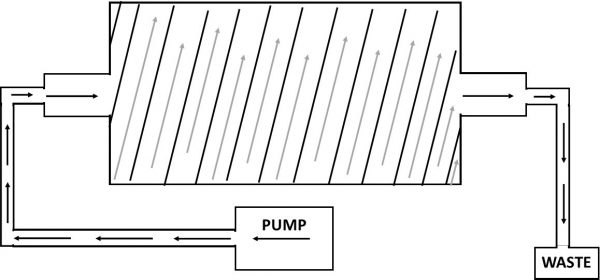

Acid flushing involves pumping an acidic cleaning solution through the internal flow passages on used heat transfer rolls. MPP uses this procedure to loosen deposits and blockages, which results in improving the roll’s flow rate and thermal efficiency.

Acid flushing involves pumping an acidic cleaning solution through the internal flow passages on used heat transfer rolls. MPP uses this procedure to loosen deposits and blockages, which results in improving the roll’s flow rate and thermal efficiency.

Why Acid Flushing is critical:

Basically, acid flushing is similar to changing the oil in your car's engine. Applied correctly and with regularity it can improve the life of your heat transfer rolls.

What acid flushing helps to prevent and why it’s important:

Acid Flushing addresses the removal of:

- Mineral Scaling

- Corrosion buildup: Iron Oxide (Rust)

- Blocking that could be present

Hot Spots:

When any of these 3 factors occur, a hot spot within the heat transfer roll can be created. The hot spot is where reduced heat transfer occurs. We know that a reduced heat transfer spot can often develop into worse heat transfer issues, causing the roll to lessen its ability to work.

Hot Spot Symptoms:

- Product sticking to the roll

- Visual defects occur on the product

- Inconsistent temperature across the roll body

How We Record Results:

Before the procedure, MP&P measures the initial flow and pressure through the roll This measurement gives us a baseline on just how badly the condition of the inside of the roll is. When the procedure is complete, the same test is performed to determine if flow has improved. If a significant amount of debris is removed and rinse water remains dirty, MP&P will recommend a second flush for the roll to be returned to optimal condition

Contact MP&P today to discuss how we can provide the level of service that maintains your rolls in a productive condition.