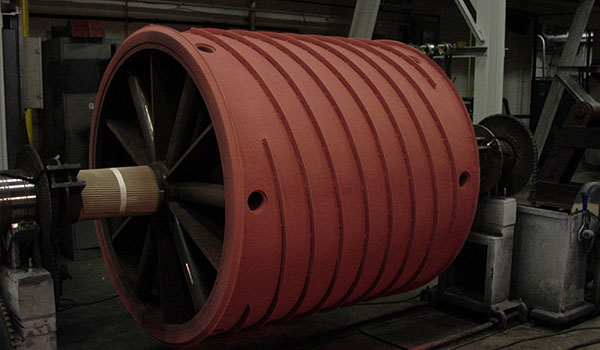

EZ Release™ Coating

Our full range of finishing capabilities include our EZ Release Industrial Coatings which can be produced in a wide variety of surface finishes/profiles to meet your specific release or traction release requirements.

Our EZ Release Series Coatings

DESIGNED TO MEET A WIDE RANGE OF INDUSTRY NEEDS

With over 70 years of experience, our team has the expertise and commitment to excellence to meet an array of industrial requirements and help you determine the optimal finish for your application. Learn all about our various EZ Release Industrial Coatings below and then contact us to discuss your application’s specific needs. We are confident that we can provide you with a surface that meets or exceeds your expectations, bringing incremental value to your organization on an ongoing basis.

Paper Mill Grade

Our EZ Release MP1000 Series is an excellent choice for dryer drums and film casting applications. Contact us so that we may help you determine if this finish is right for your application. Below are the specifications of this paper mill grade coating.

Our EZ Release MP1000 Series is an excellent choice for dryer drums and film casting applications. Contact us so that we may help you determine if this finish is right for your application. Below are the specifications of this paper mill grade coating.

- Pure Flouropolymer Coating melts and flows during curing to provide a non-porous film.

- Excellent thermal conductivity due to thin film builds of less than 1.5 mils directly over chrome.

- Excellent nonstick properties, chemical resistance and low friction.

- Suitable for continuous in use temperatures up to 400°F, intermittent to 450°F

Standard

Our EZ Release MP2000 Series has a wide range of uses and is a great choice for laminating rolls, size press rolls, carrying rolls, idler rolls, cooling and heating rolls, dryer drums and coating sections. Read the specifications below and get in touch with us to learn more.

- Pure Flouropolymer Coating melts and flows during curing to provide a non-porous film

- Additional benefits of higher continuous in use temperatures up to 500°F, intermittent to 550°F

- Good thermal conductivity with film thicknesses of 3 – 4 mils.

- Greater toughness and outstanding coating performance make this system applicable to a wide variety of end uses.

Abrasion Resistant

Our EZ Release MP3000 Series is an abrasion resistant coating and an excellent choice for abrasive web application's particularly in laminating, paper and conversion applications. Below are the specifications of this roll finish.

Our EZ Release MP3000 Series is an abrasion resistant coating and an excellent choice for abrasive web application's particularly in laminating, paper and conversion applications. Below are the specifications of this roll finish.

- Pure Flouropolymer Coating melts and flows during curing to provide a non-porous film

- Similar properties to our standard MP2000 series, plus 6 -10 times the abrasion resistance.

- Good thermal conductivity with film thicknesses of 5 – 6 mils.

Permeation Resistant

Our EZ Release MP4000 Series coating is permeation resistant and a great choice for coating roll internals when re-shelling a roll or for roll surfaces running in emersion.

Our EZ Release MP4000 Series coating is permeation resistant and a great choice for coating roll internals when re-shelling a roll or for roll surfaces running in emersion.

- Pure Flouropolymer Coating melts and flows during curing to provide a non-porous film.

- Similar properties to our standard MP2000 series, plus twice the permeation resistance.

- A multilayered system capable of producing film thicknesses up to 40 mils.

NiCr

- Pure Flouropolymer Coating melts and flows during curing to provide a non-porous film.

- All the same properties of our MP1000 Paper Mill Grade with the exception of a thermal sprayed NiCr substrate.

Enhanced Release

Our EZ Release MP6000 Series coating is an excellent choice for laminating applications and film casting applications particularly when exposed to harsh chemical environments. This coating contains properties that make it a strong chemical resistant and low friction. Learn more below and contact us to discuss your specific application requirements.- Pure Flouropolymer Coating melts and flows during curing to provide a non-porous film.

- Excellent nonstick properties, excellent chemical resistance and low friction.

- Excellent thermal conductivity with film builds up to 2.5 mils.

- Suitable for continuous in use temperatures up to 400°F, intermittent to 450°F.

- Green pigmentation provides additional corrosion resistance relative to similar coatings.

High Temp

Our EZ Release MP7000 Series coating can handle high temperatures and is an excellent selection for paper mill and other high temperature applications. In addition to its strong heat resistance, the MP7000 series has several other benefits.

Our EZ Release MP7000 Series coating can handle high temperatures and is an excellent selection for paper mill and other high temperature applications. In addition to its strong heat resistance, the MP7000 series has several other benefits.

- Highest operating temperature of any fluoropolymer.

- Continuous in use temperatures up to 550°F, intermittent to 600°F.

- Extremely low coefficient of friction.

- Good abrasion resistance.

- Good chemical resistance.

Enhanced Release

Our EZ Release MP8000 Series coating is the perfect choice for laminating applications and film casting applications particularly when heavy nip pressures are used. Learn more below and get in touch with us to discuss your specific needs.- Pure Flouropolymer Coating melts and flows during curing to provide a non-porous film.

- Excellent nonstick properties, excellent chemical resistance and low friction.

- Excellent thermal conductivity with film builds up to 2.5 mils.

- Suitable for continuous in use temperatures up to 400°F, intermittent to 450°F.

- A Black, FDA conforming analog of our MP6000 series coating.

Specification Guide

| Property | Non-Stick | Chemical Resistance | Abrasion Resistance | Salt Spray Resistance | In Use Temperature* | FDA Approved | Color |

|---|---|---|---|---|---|---|---|

| MP1000 | Excellent | Excellent | Good | Excellent | 400-450°F | Grey | |

| MP2000 | Very Good | Excellent | Very Good | Excellent | 500-550°F | Black (sparkle) | |

| MP3000 | Very Good | Excellent | Best | Excellent | 500-550°F | Grey (sparkle) | |

| MP4000 | Very Good | Excellent | Very Good | Excellent | 500-550°F | Red (sparkle) | |

| MP5000 | Excellent | Excellent | Good | Excellent | 400-450°F | Pewter | |

| MP6000 | Excellent | Excellent | Good | Excellent | 400-450°F | Green | |

| MP7000 | Excellent | Good | Fair | Fair | 550-600°F | Green | |

| MP8000 | Excellent | Excellent | Good | Excellent | 400-450°F | Black |