Whatever the industrial roll, we service it at MP&P

Continue readingCategory Archives: Shop Talk

Shop Talk often presents information on the industrial roll business. Because there are new people coming into this industry, we provide both detailed and basic information. The pros know a lot about the industry, but not everything, and newcomers need information. One of the basic principles of success is to always be open to learn and improve.

Shop Talk often presents information on the industrial roll business. Because there are new people coming into this industry, we provide both detailed and basic information. The pros know a lot about the industry, but not everything, and newcomers need information. One of the basic principles of success is to always be open to learn and improve.

Chrome Plating By The Numbers

Chrome plating is among our primary in-house specialties that a range of customers depend upon.

Continue readingMP&P: Industrial Roll Grinding; a Process and Strategy Overview

Read about our Grinding Services and the Trained Techs that do the job.

Continue readingWhat’s so important about values?

Here at MP&P the entire company functions on an interrelated series of values which carries out to each person on our team.

Continue readingCustomer Quality

When it comes to industrial roll servicing, there are many factors that form together in order to maintain customer quality and strong relationships.

Continue readingHave you thought about the power of seamless?

As always, the industrial marketplace continues to bring new challenges and opportunities to business. In terms of opportunity, one of the ways MP&P adds value to its customers is the seamless approach to servicing your industrial rolls.

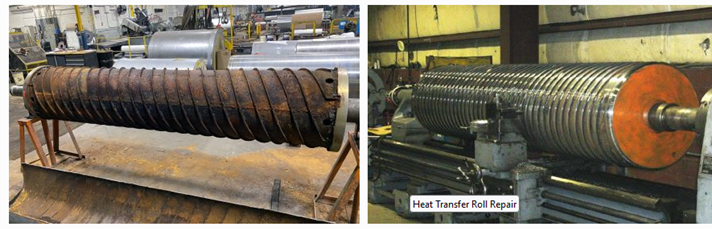

Continue readingRoll Repair

When the time comes to determine if your industrial roll requires repair or refurbishing, it’s best to talk to an MP&P engineer. They can talk you through temperature control challenges and assist you in evaluating which will work to your advantage and save you time and money. Refurbishing a roll typically provides a 30%-time savings […]

Continue readingA Quick Reference on Roll Repair

One of the key factors of performance materials with international standards is uniform temperature control. Essentially, temperature control and stability are key indicators of heat transfer roll health. Both factors impact your line speed, product quality and consistent results. Maintaining Performance Basic maintenance of your heat transfer roll is absolutely essential: Running treated water through […]

Continue readingRoll Repair Overview

Essential Factors: Temperature control and stability, These remain key factors of Heat Transfer Roll health. With growing performance materials and adherence to international standards, uniform temperature control is essential. Line speed is directly impacted. Product quality and consistency are affected. When you detect an issue with your heat transfer rolls. The key first step […]

Continue readingMatte Roll Surface Finishing. What you should know.

One of the more popular roll finishes is the Matte surface finish. This finish is often applied on heat transfer rolls resulting in a non-gloss appearance.

Continue reading